Quartz heating elements

Quartz infrared radiators

Quartz or quartz glass radiators

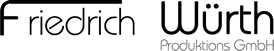

What are quartz heating elements?

Quartz heating elements are electric heating elements in which a heating wire is embedded in a quartz glass tube. When switched on, the heating wire is heated electrically and emits heat in the form of Infrared radiation directly through the transparent or translucent quartz glass.

The radiant heat generated hits surfaces or materials in a targeted manner and heats them quickly and efficiently.

Thanks to the use of quartz as a carrier material, these heating elements are particularly Temperature-resistant, fast-reacting and durable. The low thermal mass of the glass ensures that the element heats up within a few seconds and cools down again immediately if required,

Ideal for processes with precise temperature control.

Quartz heating elements are used wherever Direct heat transfer, Short heat-up times and Precise control are in demand - e.g. in drying systems, packaging machines, thermoforming systems or electronics production.

Technical features at a glance

Quartz heating elements are characterized by a number of technical features that set them apart from conventional heating elements.

In combination with fireclay storage cores, which are known for their excellent heat storage capacity, they can further increase the efficiency of heating systems.

Short heat-up time

Quartz radiators reach their operating temperature within a few seconds.

This saves energy and enables immediate readiness for use without long lead times.

High operating temperatures

Depending on the design, quartz heating elements can reach temperatures of up to 900 °C or more.

constant and uniform over longer periods of time.

Targeted radiant heat

In contrast to conventional radiators, quartz heating elements give off heat primarily via Infrared radiation from.

This hits the object to be heated directly and reduces energy losses through convection.

Low thermal mass

The low mass of the quartz tube results in a rapid temperature change - ideal for processes with dynamic temperature control.

Long service life

Thanks to the stable quartz glass and the high-quality heating wire, the elements are durable and low-maintenance when properly designed -

even with frequent switching on and off.

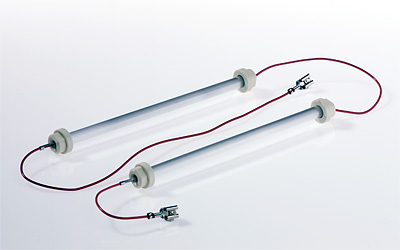

Versatile connection options

Quartz heating elements can be manufactured with different voltages and outputs

and can be easily integrated into existing systems.

Advantages over other heating elements

Quartz heating elements offer a whole range of advantages over classic heating systems such as ceramic or metal radiators - especially when precise control, fast response and high energy efficiency are required.

A decisive advantage is the extremely short heat-up time. While conventional radiators first have to heat up their surroundings, quartz radiators emit heat directly to the target object almost instantaneously via infrared radiation. This eliminates long lead times and the use of energy can be controlled much more efficiently - which is particularly advantageous in automated processes or when switching on and off frequently.

The energy distribution is also more targeted: instead of heating the air, quartz heating elements act precisely on surfaces or materials. This not only ensures lower heat losses, but also enables use in particularly sensitive or confined areas of application.

Quartz heating elements also score points with their compact design. Due to their high radiant power, they can be used in a much more space-saving manner than many conventional alternatives - a clear advantage in cramped installation situations, for example in appliances or machine modules.

Last but not least, the above-average durability is evident: quartz heating elements are just as suitable for continuous operation as they are for cycle applications with frequent load changes. Thanks to the low thermal mass and stable design, wear is low - even over many switching cycles.

Areas of application for quartz heating elements

Quartz heating elements are used wherever heat is required quickly, precisely and reliably. Quartz heaters have established themselves as a powerful solution, particularly in industrial processes where materials need to be heated or dried directly.

In drying and painting systems, they ensure that moisture or solvents evaporate evenly and quickly - without heating up the environment excessively. In plastics processing, such as thermoforming or welding, the precise supply of heat from quartz radiators is also indispensable for shortening process times and making results reproducible.

Another typical field of application is packaging technology. Here, quartz heating elements are often used for shrinking applications, sealing processes or heating films. Their fast reaction time allows the temperature to be precisely adjusted to the respective cycle or product change - which not only saves energy, but also increases the quality of the end product.

In electronics production or medical technology, they enable non-contact, contamination-free heat transfer - for example when curing adhesives, drying sensitive components or for sterile applications. Quartz heating elements are also ideal for special solutions such as laboratory equipment or compact heating modules in appliances - especially as they can be flexibly integrated in various designs and power levels.

Whether in mechanical engineering, food technology or special applications - quartz heating elements offer advantages wherever precision, speed and process reliability are required.